Exactly How Stretch Wrapper Repair Service Works: A Comprehensive Overview to Keeping Your Equipment Functional

Stretch wrapper repair is important for keeping the effectiveness and reliability of packaging procedures. Technicians usually run into different problems that can prevent efficiency. A systematic technique is important for effective repair services. Recognizing common issues and having the right tools can make a considerable difference. Furthermore, recognizing when to execute preventative upkeep can prolong devices life. This overview explores the ins and outs of stretch wrapper repair service and what it takes to keep equipment in optimal problem.

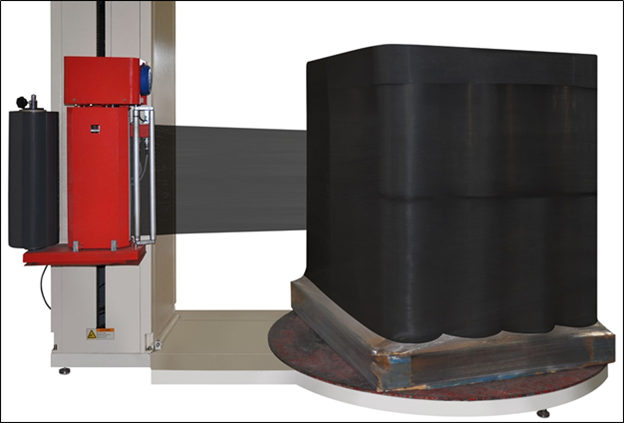

Understanding Typical Stretch Wrapper Issues

As the need for reliable product packaging solutions boosts, recognizing usual stretch wrapper problems ends up being essential for keeping functional performance. Stretch wrappers usually experience a number of prevalent troubles that can interrupt process. One usual problem is irregular film stress, which can result in poor lots stability. This disparity might be because of misaligned settings or worn-out elements. stretch wrapper repair. Furthermore, film tearing often occurs, leading to squandered products and time. Incorrect loading strategies or improper movie kind can add to this problem.Another problem involves the device's electrical components, which can malfunction and cause functional delays. Normal maintenance is necessary to ensure that electronic systems, such as electric motors and sensors, function properly. Lastly, mechanical jams might take place, frequently coming from particles build-up or worn equipments. Awareness of these issues enables operators to proactively resolve them, inevitably boosting the dependability and effectiveness of stretch covering operations

Tools Required for Stretch Wrapper Services

Effective repair services on stretch wrappers need a specific collection of devices customized to deal with the usual problems determined previously. Essential devices include an outlet and wrench collection for loosening and tightening screws, which is crucial for accessing inner parts. A multimeter is required for identifying electric troubles, enabling specialists to determine voltage and continuity in the system. In addition, screwdrivers of different dimensions are important for eliminating panels and accessing components that might need substitute or adjustment.A tape step helps ensure accurate positioning throughout repairs, while pliers can assist in gripping and adjusting smaller elements. Lubes and cleaning up agents are additionally essential for preserving smooth procedure and protecting against wear. Finally, safety gear such as handwear covers and safety glasses ought to be consisted of to safeguard the specialist during the repair procedure. By furnishing themselves with these tools, specialists can properly resolve a variety of concerns that might arise in stretch wrappers.

Step-by-Step Fixing Refine

Begin the repair service procedure by making certain the stretch wrapper is powered off and separated from the electric supply. Next, examine the machine for noticeable indications of damages or wear, concentrating on vital parts such as the film carriage, rollers, and sensing units. Eliminate them very carefully using ideal tools.Document the disassembly process to aid in reassembly if any parts appear malfunctioning. Change damaged components with OEM parts to preserve performance standards. After setting up repairs, reconstruct the maker, guaranteeing all connections are secure and aligned properly.Once reconstructed, conduct a complete evaluation of all settings and arrangements - stretch wrapper repair. Power the machine back on and run a test cycle to verify performance. Take note of any uncommon audios or malfunctions throughout operation. Make additional modifications or get in touch with the maker's manual for fixing if required. Correctly record the repair process for future recommendation

Preventative Upkeep Strategies

Carrying out preventative upkeep techniques is important for extending the life expectancy of a stretch wrapper and ensuring peak efficiency. Normal inspections should be conducted to recognize any kind of signs of wear or damages, concentrating on essential elements such as belts, motors, and sensing units. Cleansing the device routinely helps avoid debris buildup, which can impede procedure. Lubing moving components as per the manufacturer's standards lowers friction and prolongs the life of mechanical elements.Furthermore, maintaining proper stress on the film and making sure that the movie rolls are kept properly decreases stress on the tools. Operators ought to be educated to acknowledge unusual noises or activities during procedure, as these can show potential issues prior to they rise. Developing a maintenance timetable that includes changing used components proactively can significantly minimize the danger of unexpected break downs. By sticking to these methods, businesses can boost the reliability and performance of their stretch wrappers.

Fixing Tips for Quick Fixes

In attending to common stretch wrapper problems, fast repair work techniques play an essential duty in decreasing downtime. By understanding the normal troubles that occur, drivers can execute efficient upkeep best methods. This area will explore practical remedies for quick troubleshooting.

Common Stretch Wrapper Issues

Quick Repair Work Techniques

Upkeep Finest Practices

While normal maintenance is necessary for excellent performance, implementing ideal techniques for troubleshooting can also cause fast fixes. Determining and dealing with common issues without delay is essential. Operators must familiarize check over here themselves with the stretch wrapper's guidebook, as it frequently includes useful troubleshooting tips. Consistently inspecting parts like rollers, belts, and electric links can protect against minor issues from intensifying. Keeping a log of recurring issues helps identify patterns and services. In addition, keeping a clean workspace reduces the risk of particles influencing equipment functionality. When experiencing a mistake, reactivating the maker can resolve several short-term problems. Utilizing manufacturer resources and on-line discussion forums can likewise use quick understandings from experienced customers, making certain that tools continues to be functional with marginal downtime.

When to Call a Professional Service Technician

When should one take into consideration connecting to a professional technician for stretch wrapper fixings? Typically, a professional need to be gotten in touch with when the equipment experiences persistent issues that can not be dealt with via standard troubleshooting. If the stretch wrapper constantly stops working to operate, shows mistake codes, or if elements such as the electric motor or control panel show indications of damages, specialist support is called for. In addition, if the equipment calls for specialized tools or understanding for repair service, getting a service technician ensures an appropriate resolution.Moreover, when the repair tries outcome in extra complex problems or when downtime impacts manufacturing timetables considerably, professional treatment may be required. Normal maintenance checks can aid in identifying possible issues early, once a breakdown occurs that surpasses the driver's ability, it is prudent to call a specialist. This approach not only guarantees effective repair work however also preserves functional performance and safety within the workplace.

Best Practices for Equipment Longevity

To guarantee the longevity of stretch covering tools, a normal maintenance schedule is important. Complying with appropriate usage techniques additionally plays an important function in decreasing wear and tear. Executing these best methods can significantly prolong the lifespan of the machinery.

Regular Upkeep Set Up

A well-structured regular upkeep timetable is essential for making certain the long life of stretch wrapping tools. This routine must consist of daily, weekly, and regular monthly tasks customized to the specific model and use conditions. Daily assessments ought to concentrate on examining for indicators of wear, ensuring appropriate tension, and verifying that safety features are functional. Weekly upkeep can involve cleaning the device and lubricating moving parts to minimize friction. stretch wrapper repair. Monthly evaluations need to encompass a thorough exam of top article electric parts and drive systems. Maintaining detailed documents of upkeep tasks aids in determining patterns or persisting concerns, promoting timely treatments. Following this routine not only extends tools life however likewise boosts effectiveness, minimizing downtime and repair work expenses

Correct Use Techniques

Regular upkeep is only one aspect of optimizing the life-span of stretch covering devices; correct use strategies additionally play a substantial duty in boosting efficiency and toughness. Operators ought to be educated effectively to guarantee they recognize the devices's performances and restrictions. Continually sticking to the producer's guidelines for lots dimensions and wrapping patterns is important. In addition, maintaining a tidy operating environment assists prevent particles build-up, which can restrain the maker's performance. It is important to keep an eye on the stress settings to stop over-stretching or under-stretching the film, both of which can result in inefficient covering. Validating that the tools is operated within its defined parameters will lessen wear and tear, ultimately extending its functional life and lowering the need for repairs.

Frequently Asked Concerns

How Often Should I Do Regular Upkeep on My Stretch Wrapper?

Regular maintenance on a stretch wrapper ought to ideally be executed every three to 6 months, depending upon use. Routine checks can stop break downs and ensure peak efficiency, extending the equipment's lifespan and boosting operational performance.

What Are the Signs Showing My Stretch Wrapper Needs Immediate Repair Service?

Signs that a stretch wrapper needs prompt repair service include uncommon sounds during operation, irregular wrapping stress, error messages on the control panel, and visible damage to components, showing possible failing that requires punctual attention to stop further problems.

Can I Make Use Of Any Type Of Lubricant for My Stretch Wrapper Parts?

Utilizing any kind of lubricating substance on stretch wrapper components might cause issues. It is essential to make use of manufacturer-recommended lubricating substances to assure peak performance and protect against damages, as conflict can result in malfunctions and raised maintenance prices.

How Do I Choose the Right Stretch Cover for My Maker?

Selecting the suitable stretch cover includes taking into consideration maker requirements, load kind, and environmental aspects. Reviewing stretchability, density, and width warranties ideal performance, protecting against damage while keeping item honesty throughout storage space and transportation. Appropriate option is crucial.

Is It Safe to Run a Malfunctioning Stretch Wrapper Temporarily?

Operating a malfunctioning stretch wrapper, also momentarily, see this here poses substantial security threats. It can result in further equipment damage and boost the likelihood of mishaps, threatening both driver safety and security and overall efficiency in the office. As the need for reliable product packaging remedies raises, understanding typical stretch wrapper problems comes to be essential for maintaining operational performance. Reliable fixings on stretch wrappers need a certain collection of devices tailored to address the typical issues determined earlier. In dealing with usual stretch wrapper problems, quick repair strategies play a crucial duty in minimizing downtime. Addressing these common stretch wrapper concerns immediately ensures minimal downtime, preserving productivity and performance in packaging operations. Making use of any kind of lubricant on stretch wrapper elements might lead to problems.